Views: 0 Author: Site Editor Publish Time: 2025-10-09 Origin: Site

In upholstered furniture manufacturing, adhesive technology is a fundamental factor determining structural integrity, comfort, durability, and environmental performance. From fixing seat frames and assembling multi-layer sofa structures to laminating foam in mattresses, every stage relies on precise and reliable bonding.

Guangdong YRBEST High Polymer Technology Co., Ltd. is dedicated to providing the furniture industry with complete bonding solutions — encompassing specialized adhesives, scientific application methods, and efficient adhesive supply systems — empowering manufacturing upgrades and ensuring every piece of furniture is both durable and comfortable.

Upholstered furniture production poses a range of challenges — including bonding between diverse materials (foam, non-woven fabric, wood, metal frames, leather/PU), complex stress conditions, stringent VOC and odor standards, and the ever-growing demand for production efficiency.

To address these issues, we offer a complete series of specialized adhesives, rather than a one-size-fits-all glue:

Ideal for multi-dimensional and contoured surfaces that require rapid positioning, such as seat and sofa frame assembly.

Spray Adhesive 3006 features strong initial tack and high ultimate strength, making it suitable for demanding applications like automotive seats.

4001A/B and 4002A/B Series are engineered for internal sofa components such as pocket springs and multi-layer foam composites. They offer excellent penetration and flexibility, effectively absorbing vibration and deformation during long-term use.

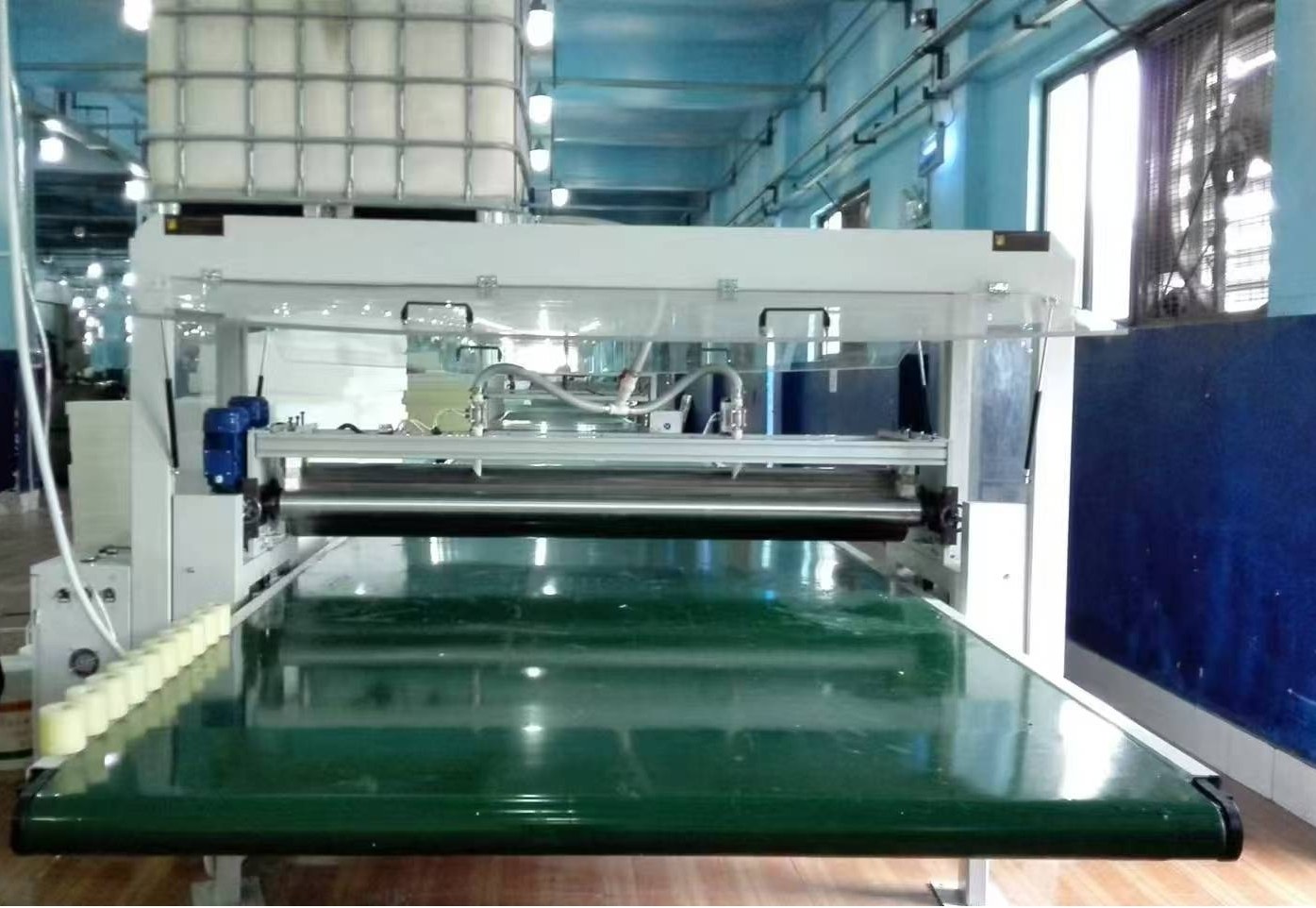

Designed for flat and large-area bonding applications, such as mattresses and panel lamination. These adhesives exhibit superior leveling properties, ensuring uniform coating during roller application. They help avoid glue starvation or overflow, maintain a smooth and strong bondline, and support fast-drying requirements for high-speed production.

We also provide solutions that meet specific needs — including low-odor formulations, flame-retardant adhesives, and water-based systems compliant with international environmental and safety standards, ensuring full alignment with market trends and regulatory requirements.

Our philosophy: For every material combination, structural component, and production process — there is an optimized environmentally friendly adhesive solution.

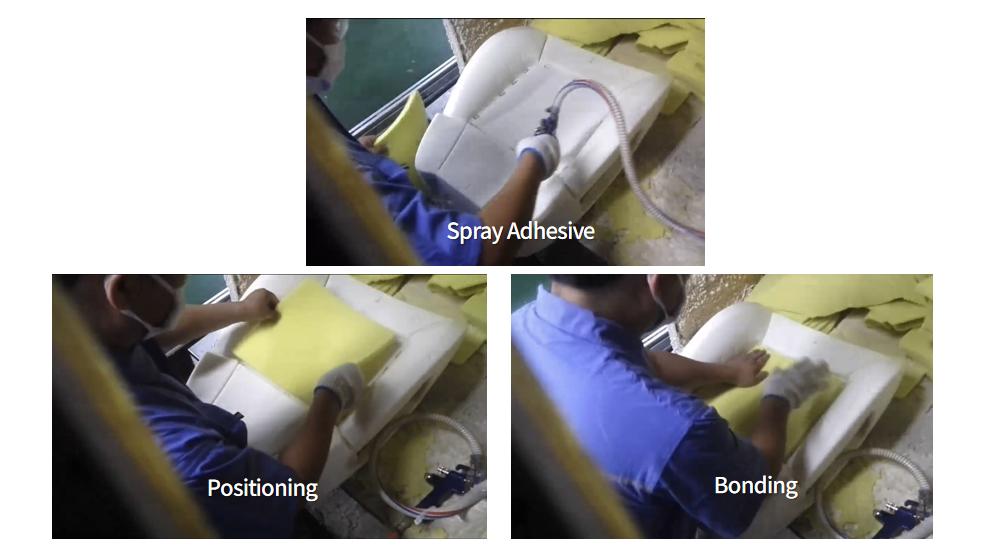

Proper adhesive application is key to achieving the desired bond strength and long-term performance. Below are the recommended procedures for the two most common methods:

1. Surface Preparation: Ensure bonding surfaces are clean, dry, and free from oil, dust, or contaminants.

2. Uniform Spraying: Maintain the recommended spray distance and speed to form a thin, even, continuous adhesive film. Avoid excessive buildup, which can cause pooling or slow solvent evaporation.

3. Open Time: Allow the adhesive to flash off (for solvent-based products) or reach its optimal tack level before assembly. Refer to product data sheets for specific open times, as temperature and humidity will influence drying behavior.

4. Accurate Lamination: Within the optimal tack window, precisely align the substrates and laminate them firmly in one pass.

5. Pressurization: Apply appropriate pressure (e.g., using a hand roller or mechanical press) to eliminate air pockets and ensure full surface contact.

6. Curing: Allow sufficient curing time before handling or further processing to ensure the bond reaches full strength.

(Best suited for large-area, planar bonding applications.)

1. Surface Preparation: Clean all bonding substrates thoroughly.

2. Adhesive Loading: Pour adhesive into the roller coater tank or connect it to the automatic supply line.

3. Roller Setup: Select rollers with suitable material and hardness according to substrate characteristics.

4. Pressure Control: Adjust roller-to-substrate contact pressure carefully. Too much pressure can deform the roller, causing uneven coating or foam damage. Too little pressure may lead to streaks or incomplete coverage.Optimal condition: slight indentation of the roller into the foam, forming a continuous, uniform film.

5. Even Coating: Apply adhesive in a consistent, single-direction pass — avoid back-and-forth rolling.

6. Immediate Lamination: Since roll-applied adhesives typically have short open times, align and bond the substrates immediately.

7. Pressing & Curing: Apply consistent pressure using a roller or platen press, then allow sufficient curing time for bond stabilization.

Even the best adhesive must be delivered through a stable and precise supply system to ensure consistent application quality. YRBEST provides multiple adhesive feeding solutions tailored to different production scales and layouts:

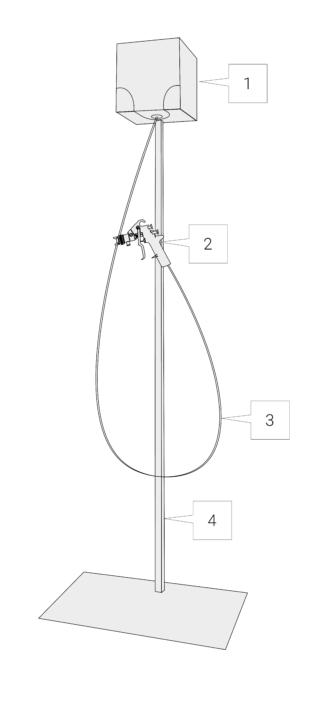

Gravity-Feed Supply System:

Simple and reliable, utilizing gravity flow. Ideal for flexible workshops with mobile workstations. Recommended container height: ≥1.8 m; one tank can serve 1–2 stations.

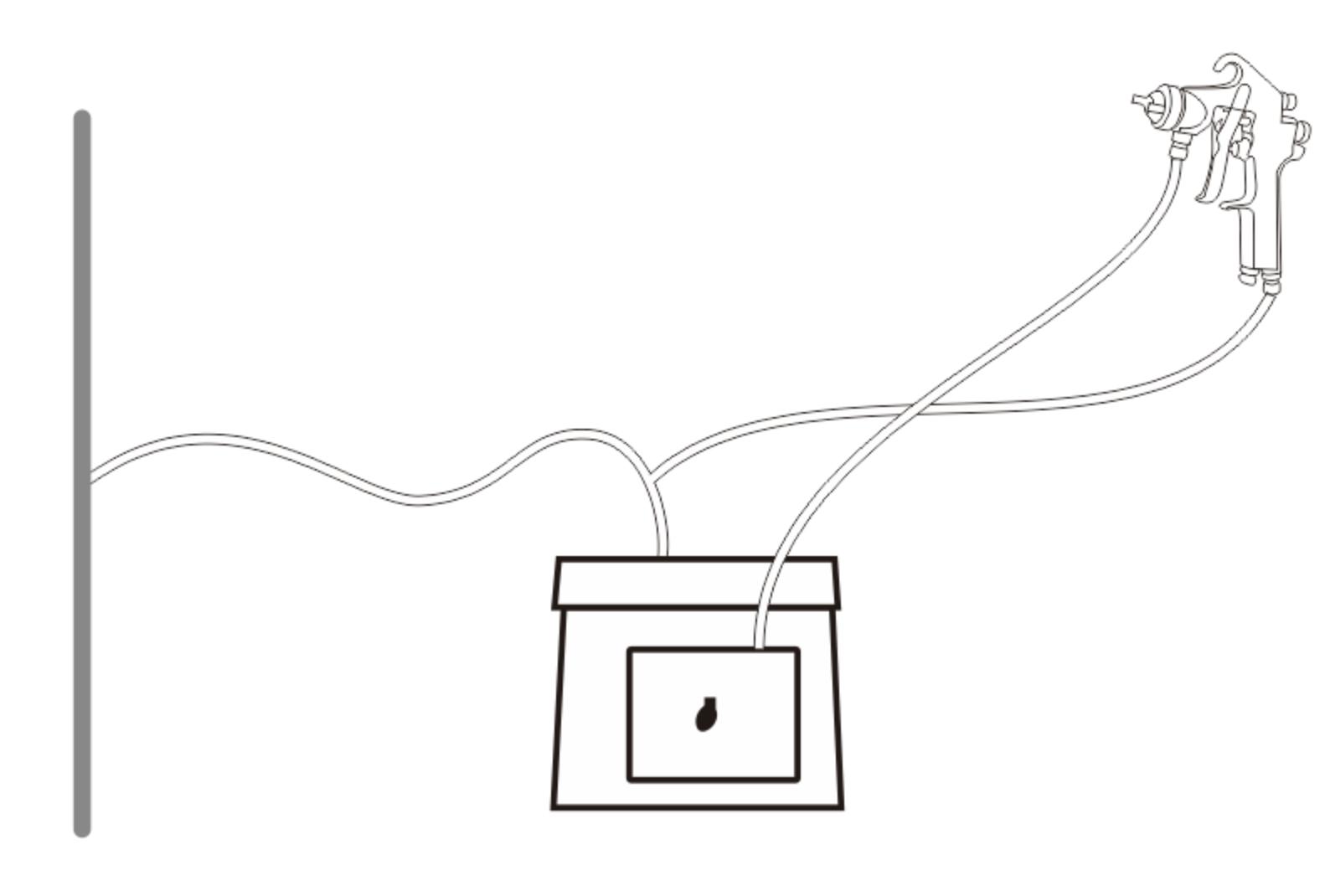

Pressure Pot Supply System:

Driven by compressed air, suitable for workshops with low ceilings or long horizontal feeding distances. One pressure pot can stably supply 3–4 workstations. Clear pressure parameters are provided for various adhesive types to maintain consistent performance.

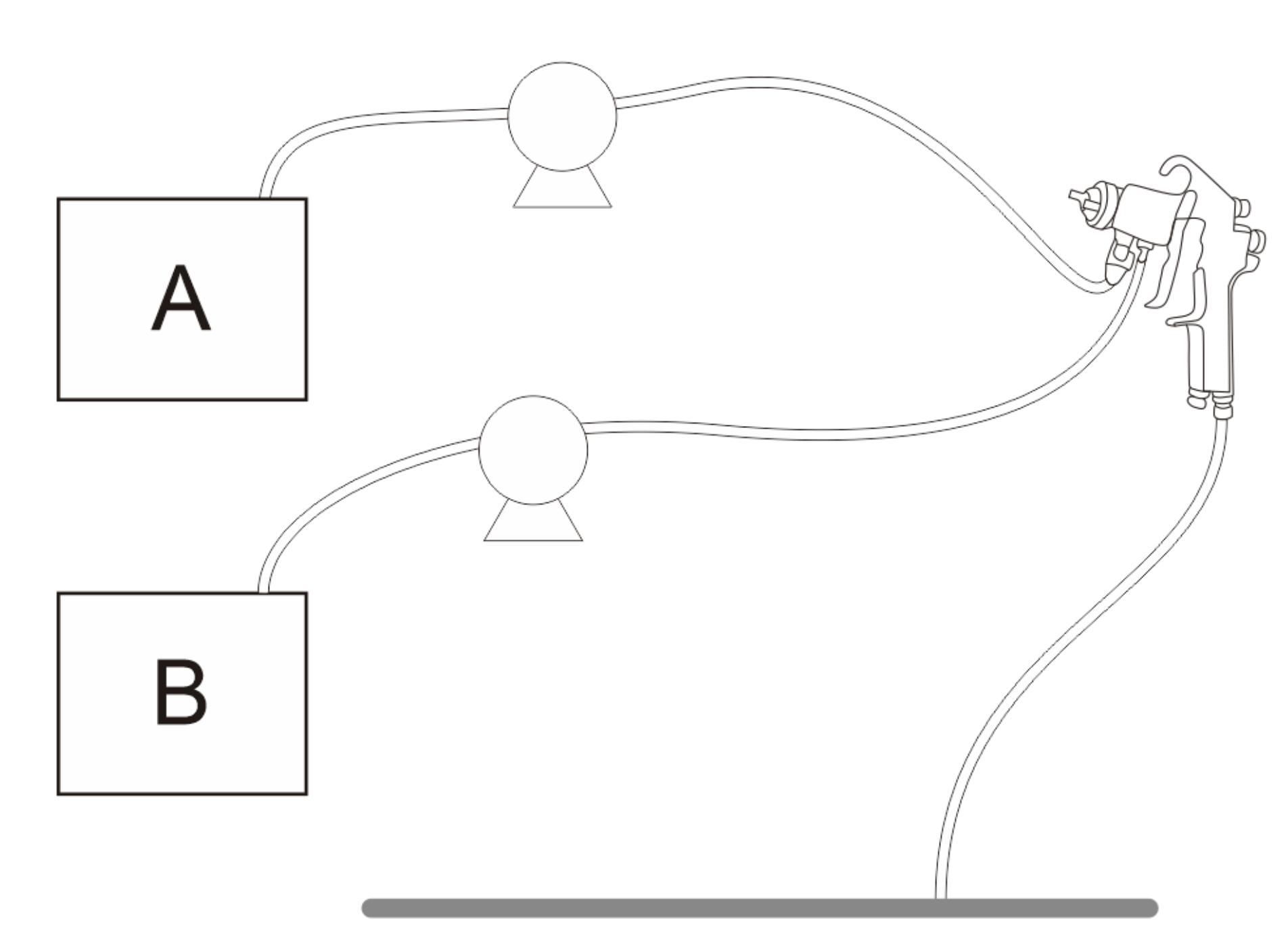

Diaphragm Pump Supply System:

A high-power option ideal for large-scale or centralized supply setups. One pump can serve multiple workstations — perfect for long-distance delivery, two-component water-based adhesives, or environments with limited forklift access.

Gravity-Feed System for Roll Coating:

Specifically optimized for roll-coating processes. The simple design enables fast, consistent adhesive flow, precise dosage control, and efficient usage — reducing waste and supporting rapid production cycles.

In modern upholstered furniture manufacturing — where quality, efficiency, and sustainability are paramount — a successful bonding solution represents the integration of materials science, process engineering, and adhesive system design.

Guangdong YRBEST High Polymer Technology Co., Ltd. is your trusted partner in this process — delivering expert support from product selection and application guidance to complete adhesive system integration, helping you achieve superior, long-lasting results in every furniture piece.